Basics of a Finned Tubular Heater

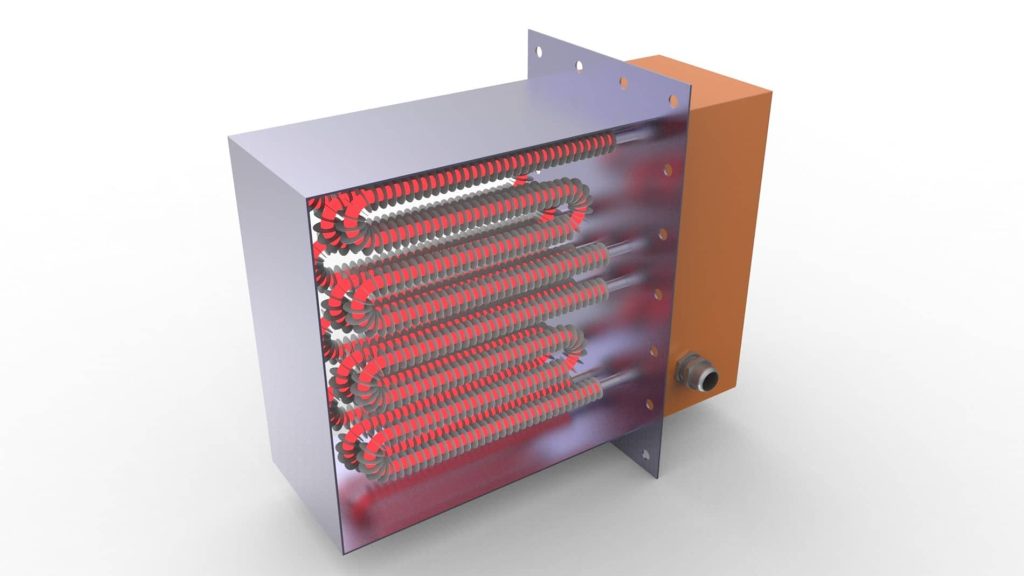

Finned tubular heaters are a type of electric heating element. They consist of a metal tube with external fins attached to its surface. The core of the heater houses a heating element. This element generates heat when electricity passes through it. The fins on the exterior serve a crucial purpose. They increase the surface area for heat dissipation.

Key Components of a Finned Tubular Heater

- Metal Tube: Usually made of stainless steel or copper

- Heating Element: Typically, a resistive wire

- Fins: Attached to the exterior of the tube

- Insulation: Surrounds the heating element inside the tube

- Terminal Connections: For electrical power input

Applications of a Finned Tubular Heater

The versatility of finned tubular heaters makes them suitable for various applications. They are used across various industries and settings. Here are some common applications:

Industrial Applications

- Process Heating: Used in manufacturing processes requiring precise temperature control

- Food Processing: For heating ovens, fryers, and other food preparation equipment

- Chemical Processing: In reactors and vessels requiring controlled heating

- Plastics Industry: For heating molds and extruders

HVAC Applications

- Air Duct Heating: For warming the air in ventilation systems

- Frost Prevention: Used in refrigeration systems to prevent frost buildup

- Space Heating: In large industrial or commercial spaces

Other Applications

- Automotive: In engine block heaters and defrosting systems

- Marine: For heating systems on ships and offshore platforms

- Agriculture: In greenhouse heating and animal husbandry

The wide range of applications demonstrates the versatility and effectiveness of finned tubular heaters. They can be adapted to meet specific heating needs across diverse industries.